July 8, 2020 – RealWear, Inc., a provider of hands-free head-mounted tablets for digital transformation in industry, has announced a new partnership with Deutsche Telekom as part of its 5G Campus Network strategy for smart factories for digital transformation. RealWear offers a range of head-worn devices that it states “transcend tablets and smart glasses”, as they are effectively a combination of the two, providing wearers with a hands-free solution for connected working.

Through the use of RealWear’s headsets within 5G Campus Network-enabled sites, industrial workers will have voice-activated access to data from different systems, such as production planning, suppliers, scheduling and dispatching.

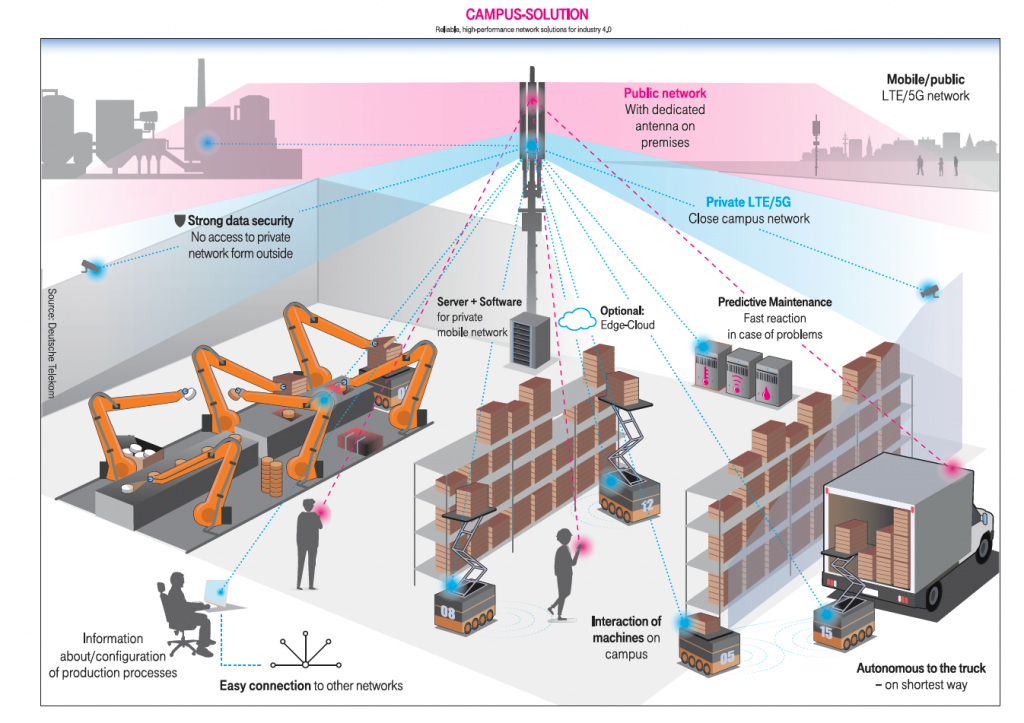

Deutsche Telekom’s 5G Campus Networks portfolio comprises different offers for enterprise customers. Either as a combination of public and private mobile networks, or a 5G private only network for a defined local “campus”, such as an office building or factory. According to the company, these campuses offer high bandwidth, short latencies and improved availability and data security, which could be helpful to industrial companies looking to bring digital transformation to the frontline.

“Strong partnerships are a key part of Deutsche Telekom’s integrated solution approach to provide end-to-end Campus Network offerings to our industrial customers,” said Antje Williams, SVP 5G Campus Networks at Deutsche Telekom. “RealWear, [as a] member of our 5G partner ecosystem, contributes with specialist know-how in the field of industry 4.0. I look forward to intensive collaboration to co-create and integrate new solutions together.”

Sanjay Jhawar, President of RealWear, commented: “Our customers are dramatically accelerating their digital transformation efforts to protect their workforce and ensure business continuity in this new normal”. Jhawar added, “Beginning in July, we invite our European industrial customers to the CCI to see the possibilities enabled by 5G and industrial head-mounted devices.”

RealWear states that industrial and field workers are often required to work in no or low bandwidth areas, making remote service support challenging. Furthermore, the company added that the need for digital transformation within the industrial setting has accelerated as a result of the COVID-19 pandemic, and has now made the network characteristics of 5G technologies critical infrastructure for business continuity.

The two companies anticipate that through the combination of RealWear’s headsets and Deutsche Telekom’s 5G technology, it will enable organizations, such as manufacturing and field services, to increase insight, productivity, flexibility and sustainability across their organizations.

Beginning July 7, Deutsche Telekom, alongside RealWear and oculavis GmbH, will begin showcasing use cases of the 5G Campus Network within The Center Connected Industry’s (CCI) “knowledge transfer factory”. The CCI is located at the RWTH Aachen Campus in Germany, and is a technology test field equipped to drive the vision of networking companies, machines, systems and users, allowing people to explore and experience use cases and accelerate innovation.

Image credit: RealWear / Deutsche Telekom

About the author

Sam is the Founder and Managing Editor of Auganix. With a background in research and report writing, he has been covering XR industry news for the past seven years.