In Virtual Reality News

April 1, 2024 – North American railway company BNSF Railway has recently announced that it is currently implementing immersive technology into its mechanical training programs to keep workers safe, utilizing virtual, augmented and mixed reality (VR/AR/MR) to enhance safety strategies and improve role readiness amongst the mechanical workforce.

BNSF stated that with the help of its VR Learning Solutions provider, Roundtable Learning, the training simulations currently being tested are designed to address risk-specific scenarios in order to help workers avoid potential incidents and injuries while on the job.

The VR training programs complement BNSF’s existing instructor-led mechanical programs by reinforcing learning techniques that cannot be replicated in traditional training modalities. Built for in-depth exposure to step-by-step processes, the VR program provides experiential learning opportunities for mechanical employees to build their knowledge of the importance of personal protection equipment (PPE), improve risk awareness, and hone other procedures. Each time employees encounter safety hazards within the VR experience, warnings alert learners to pressurized systems and reinforce safe lifting practices.

Christopher Skinner, locomotive mechanical manager at BNSF, said: “One of the big reasons BNSF chose to deploy VR training within the mechanical arena is consistency. You have control of a standardized method of delivering training. With instructor-led training, the message can vary depending upon the instructor and location, so there’s a possibility of losing critical information. With VR training, mechanical students receive precisely the same information across the company.”

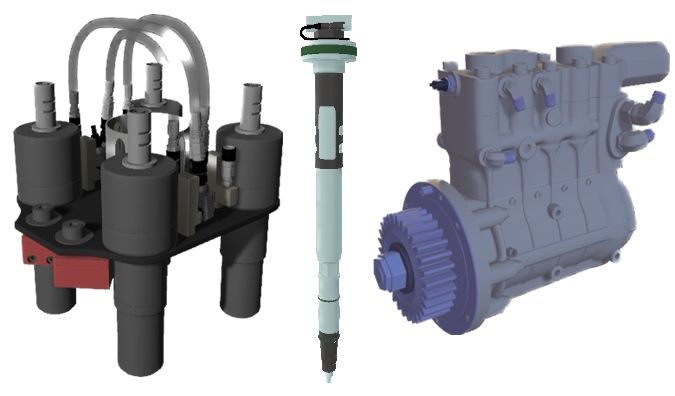

BNSF stated that it had to build accurate 3D models that had the right level of detail for the immersive training. This included anything from the locomotives themselves, to the shop environment, or individual components and tooling. In many cases, where a digital equivalent of a tool or part didn’t exist, experts within the BNSF Technical Training Center had to make one.

“We really had to kind of reverse-engineer the locomotive to build the components that we needed,” added Skinner. “We’d obtain the physical component and take multiple photos from different angles, with a tape measure or ruler for perspective.” With that information, a digital component was created.

In the above training video from BNSF, a trainee appears to be utilizing a HTC VIVE Pro VR headset, along with the HaptX Gloves DK2, meaning trainees will also be getting an enhanced sense of immersion thanks to haptic feedback provided by the gloves when interacting with virtual objects.

Commenting on the VR training program, Roundtable Learning’s Jeff Suchan said: “BNSF took the initiative to think outside the box by providing their employees with a new training strategy to further practice identifying and mitigating exposures to risk. Not only has this created a new way of learning and training at BNSF, but these technologies can also help create safer behaviors within the rail industry as a whole.”

According to Mark Stockman, BNSF’s director of mechanical training, the company closed out last year with the lowest injury frequency rate in its 175-year history. This latest VR training initiative is therefore aimed at keeping BNSF’s commitment for safety front and center, whilst simultaneously upholding the company’s standards of innovation.

BNSF added that it continues to invest in new technologies such as VR simulations to further enhance its mechanical training programs, and that such technologies serve as an integral tool in bridging frontline work with digital enhancements in order to prioritize the company’s vision of an accident and injury-free workplace. Finally, the company noted that over time it aims to expand the range of VR coursework available, offering trainees a large library spanning various departments and crafts.

Image credit: BNSF Railway

About the author

Sam is the Founder and Managing Editor of Auganix, where he has spent years immersed in the XR ecosystem, tracking its evolution from early prototypes to the technologies shaping the future of human experience. While primarily covering the latest AR and VR news, his interests extend to the wider world of human augmentation, from AI and robotics to haptics, wearables, and brain–computer interfaces.